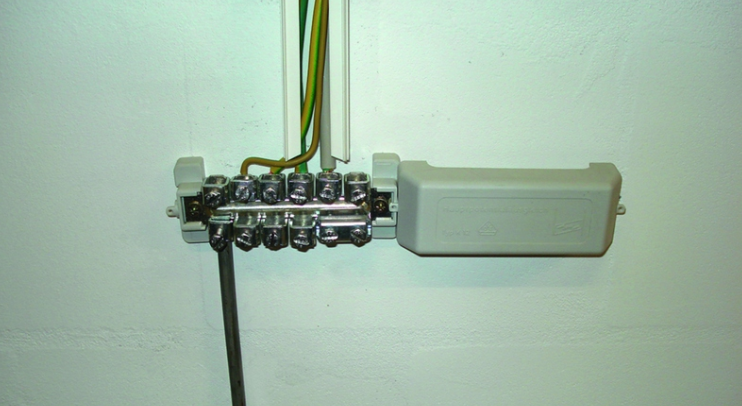

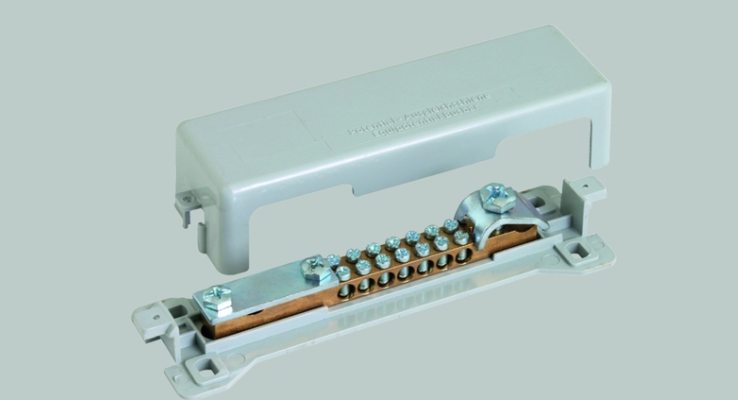

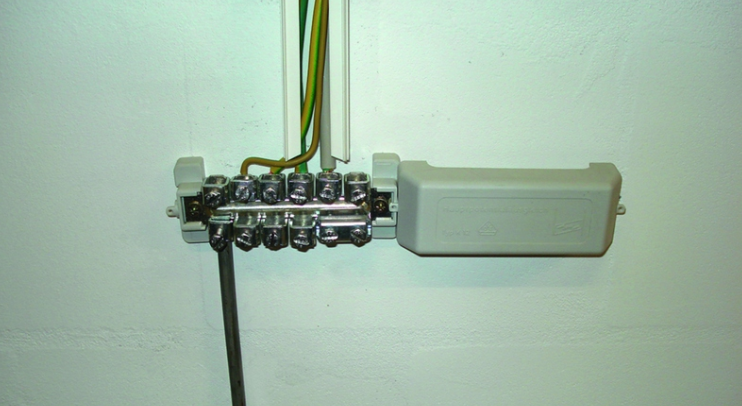

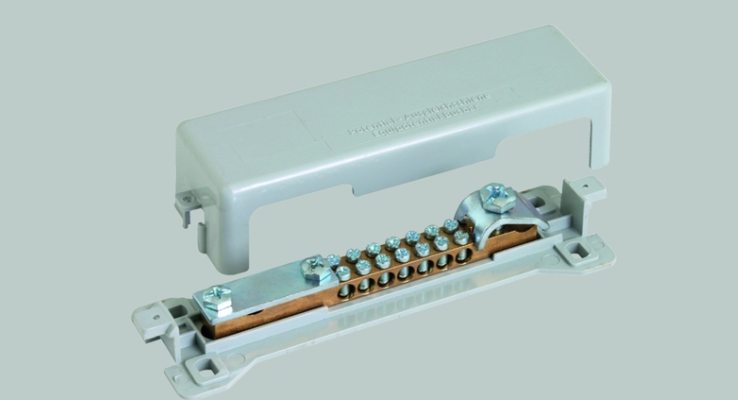

"Junyao" series grounding busbars are all made of pure 99.9% pure copper and other low-resistance busbars, with 4-20 terminals added, and fully manual grounding installation, which is an excellent auxiliary material for machine rooms and equipment grounding.

Product Details

An equipotential bar, also known as an equipotential bonding bar or grounding bar, is a conductive strip or bar used to create a common equipotential bonding point for electrical systems. It is designed to establish electrical continuity and equalize the electrical potential of various conductive components within a specific area or system.

Here are some key aspects and applications of equipotential bars:

-

Purpose and Function: The primary purpose of an equipotential bar is to provide a central point for connecting and bonding various conductive parts within an electrical system. By connecting these components to the equipotential bar, their electrical potentials are equalized, minimizing the risk of electrical shocks, mitigating electromagnetic interference, and ensuring proper grounding.

-

Construction and Design: Equipotential bars are typically made of a highly conductive material, such as copper or aluminum. They are often in the form of a long, flat strip or bar with multiple terminal points or holes for connecting conductors. The bar may be mounted on an insulating base or directly on a surface, depending on the specific installation requirements.

-

Electrical Panel Grounding: Equipotential bars are commonly used in electrical panels and distribution boards to provide a centralized grounding and bonding point. In these applications, the equipotential bar is connected to the main grounding conductor and serves as a point of connection for grounding conductors from various circuits and equipment within the panel. This helps ensure that all components within the panel are at the same electrical potential and minimizes the risk of electrical hazards.

-

Telecommunications and Data Centers: Equipotential bars are also utilized in telecommunications and data center environments. In these applications, they are used for bonding and grounding equipment racks, cabinets, and associated cabling. The equipotential bar provides a common reference point for grounding conductors, helping to maintain electrical continuity, reduce noise, and provide protection against electrical surges.

-

Lightning Protection Systems: Equipotential bars are an integral component of lightning protection systems. They are used to establish a low-impedance bonding network, connecting lightning rods, down conductors, and grounding electrodes. The equipotential bar helps ensure that all components of the lightning protection system are at the same electrical potential, allowing for effective dissipation of lightning currents and minimizing the risk of damage to structures and equipment.

Equipotential bars are crucial for establishing proper bonding and grounding in electrical systems. By creating a common reference point for electrical potentials, they help ensure safety, prevent electrical hazards, and maintain system performance. The specific design and application of equipotential bars may vary depending on the requirements and regulations of the particular industry or installation.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা

বাংলা  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  Gaeilge

Gaeilge  عربى

عربى  norsk

norsk  اردو

اردو  čeština

čeština  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  ລາວ

ລາວ  Қазақ

Қазақ  Euskal

Euskal  slovenský

slovenský  Македонски

Македонски  Română

Română  Српски

Српски  简体中文

简体中文  Afrikaans

Afrikaans  עִברִית

עִברִית  יידיש

יידיש  Беларус

Беларус  മലയാളം

മലയാളം  Hawaiian

Hawaiian  հայերեն

հայերեն